Rotary Joint Seal Kit for High Pressure Excavator PC200 PC220 Center Joint Seal Kit

1. Product Introduction

| Name |

Rotary Joint Seal Kit for High Pressure Excavator PC200 PC220 Center Joint Seal Kit |

| Hardness |

70-90 shore |

| Tempreture |

-30 ~ + 100 ° C |

| Maximum working pressure |

30 Mpa Pressure Strong Sealing Capacity |

| Quality |

Top quality |

| Material |

TPU + NBR +PTFE |

| Standard or Nonstandard |

Standard |

| MOQ |

2 sets |

| Color |

As pictures show |

Overview: Ensure peak performance and leak-free operation for your Komatsu PC200 and PC220 excavators with our premium Rotary Joint Seal Kit. Engineered to withstand extreme pressures and harsh environmental conditions, this complete seal kit restores your excavator's center joint to its original specifications, preventing hydraulic fluid leaks and protecting critical components from wear and contamination. It is an essential maintenance solution for ensuring operational efficiency and minimizing costly downtime.

Key Features & Technical Specifications:

· Precision Compatibility: Designed as a direct OEM replacement for Komatsu models PC200 and PC220. This standard kit guarantees a perfect fit and reliable performance, ensuring easy installation and a perfect seal.

· Advanced Multi-Material Construction: Manufactured from a superior blend of TPU (Thermoplastic Polyurethane), NBR (Nitrile Rubber), and PTFE (Teflon). This hybrid material combination delivers:

· High Abrasion & Tear Resistance (TPU)

· Excellent Oil and Fuel Resistance (NBR)

· Low Friction and High-Temperature Stability (PTFE) This ensures exceptional durability and long service life.

· Built for High-Pressure Applications: With a maximum working pressure of 30 MPa, this seal is engineered to handle the intense demands of modern hydraulic systems. It provides a strong, reliable seal that maintains integrity under extreme stress, preventing failure and leaks.

· Superior Temperature Resilience: Reliably performs across a wide temperature range from -30°C to +100°C, making it suitable for operation in both freezing cold and scorching hot environments without losing flexibility or sealing capability.

· Optimized Hardness: With a 70-90 Shore A hardness, the seals offer the ideal balance of flexibility for easy installation and rigidity to resist extrusion and deformation under high pressure.

· Top-Tier Quality Assurance: Every component is produced to the highest quality standards using precision engineering and rigorous quality control. This guarantees that every seal meets or exceeds original equipment specifications for performance and durability.

· Visual Reference: The product's appearance is exactly as shown in the accompanying pictures.

Applications & Benefits:

· Prevents Hydraulic Leaks: Ensures a tight seal to maintain hydraulic system pressure and efficiency.

· Extends Component Life: Protects the expensive center joint assembly from damage and wear.

· Reduces Downtime: A complete kit for efficient repairs, getting your equipment back to work faster.

· Cost-Effective Maintenance: A vital repair kit for routine maintenance or overhaul projects on Komatsu PC200 and PC220 excavators.

Ordering Information:

· Minimum Order Quantity (MOQ): 2 sets

· Product Includes: All necessary seals and O-rings required for a complete center joint reseal.

Related Excavator Number:

PC60-5PC60-6PC60-7PC75UUPC78USPC100-5PC100-6PC120-5PC450-6PC200-5PC200-7PC200-8PC220-7PC220-8PC240-7PC240-8PC270-7PC300-3PC300-5PC300-6PC300-7PC350-6PC350-7PC360-7PC360-8PC400-6PC400-7PC650 / 600 / 700-8E

2. Company Profile

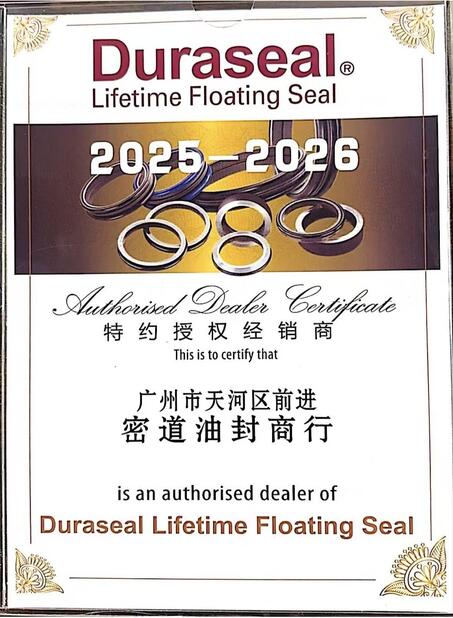

Mido Oil Seal was founded in 2007, which is a company specializing in the sale of construction machinery oil seals. Gathering oil seals from world's famous factories, with currently over 1,000 varieties in stock. The main service is construction machinery and engineering machinery.

The company has a total of three store and a warehouse now, one of which serves as the Foreign Trade Department to customer reception and product display. The most important thing is that we have a professional team for purchasing, selling, packing, shipping and after-sale service.

Our CEO Mr. Hu has been engaged in the oil seal industry since 1995. As one of the founders, he founded the Guangzhou Construction Machinery Industry Association and served as its president.

According to the actual situation of the Chinese excavator maintenance market, he has continuously studied, researched, innovated, introduced and developed high-quality oil seal repair kits that meet the real needs of the market. Ensure that customers can buy High-performance anti-leakage effect and long-term oil sealing effect. Based on technology leadership, the company has established a market research, quality assurance and after-sales service system to fully meet customers exact needs and has won excellent results in the industry. The reputation and word of mouth have won the continuous support of domestic and international counterparts and customers. Through long-term first-line services, we know that the promotion and use of high-quality oil seals are inseparable from your support and encouragement. We always adhere to the principle of quality first and benefit sharing to provide high-quality oil seals for the customers.

In addition to online sales, we also participate in exhibitions to have better face-to-face contact with customers.

The history of exhibition

2001 Beijing BICIS

2004 Shanghai Bauma

2005 Beijing BICIS

2006 Shanghai Bauma

2007 Beijing BICIS

2009 Beijing BICIS

2011 Beijing BICIS

2013 Beijing BICIS

2024 Moscow CTT

2024 Shanghai Bauma

FAQ

Q1. Why should I choose your products?

While operating our own manufacturing facility, we also distribute oil seals from renowned international brands. We are committed to providing one-stop solutions to meet all our customers' diverse needs. Excavator/ Loader/ Motor Grader Seal kits and Spare Parts.

Q2. What series of products does your company have?

Excavator/ Loader/ Motor Grader Seal kits and Spare Parts.

Q3. Any other good service your company can provide?

Yes. Conduct regular follow-up visits, and there are dedicated staff available online 24 hours a day

In the era of digital office, our company is committed to providing customers with comprehensive and efficient service experiences. The "Online Specialist Response" is a key component of this commitment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!