Repair O Ring Set Box KOBELCO SK Custom O Rings 84 SHORE

Product Details

| Name |

O-RING KIT/BOX |

| Hardness |

84 SHORE |

| Tempreture |

-30~260°C |

| Quality |

Top quality |

| Material |

NBR |

| Standard or Nonstandard |

Standard |

| Lead Time |

3-15 days after payment

|

| MOQ |

25 Box/Boxes |

| Color |

as picture show |

This premium O-Ring Kit offers a selection of standard-sized, industrial-grade nitrile rubber O-rings designed for reliability across various applications. With a hardness of 84 Shore A and an extended operating temperature range, these O-rings are ideal for use in automotive, hydraulic, pneumatic, and general industrial systems requiring solid sealing performance under challenging conditions.

Technical Specifications

· Material: NBR (Nitrile Rubber)

· Hardness (Shore A): 84 ±2

· Operating Temperature Range: -30°C to +260°C

· Product Quality: Top Industrial Grade

· Standard/Nonstandard: Standard (AS568 or equivalent)

Key Features

· High-Temperature Resistance – Reliable performance up to 260°C

· Oil and Fuel Resistance – Excellent compatibility with oils, fuels, and many chemicals

· Consistent Hardness – 84 Shore A ensures durable and dependable sealing

· Wide Temperature Suitability – Functions effectively in both low and high-temperature environments

· Long Service Life – Resists compression set and maintains elasticity

Packaging & Ordering Info

· Packaging: Organized in a clearly labeled box

· Minimum Order Quantity (MOQ): 25 boxes

· Lead Time: 3–15 days after payment confirmation

· Color: As shown in product images

Applications

· Hydraulic and pneumatic systems

· Automotive engines and fuel systems

· Industrial machinery and equipment

· General maintenance and repair

· MRO (Maintenance, Repair, and Operations)

Quality Assurance

Manufactured under strict quality control standards, these O-rings ensure consistent sizing, material properties, and sealing performance. Each kit is carefully packaged to prevent damage and maintain integrity during shipping and storage.

This O-Ring Kit provides a practical and cost-effective solution for professionals and industries requiring reliable, standard-sized seals capable of performing under diverse and demanding conditions.

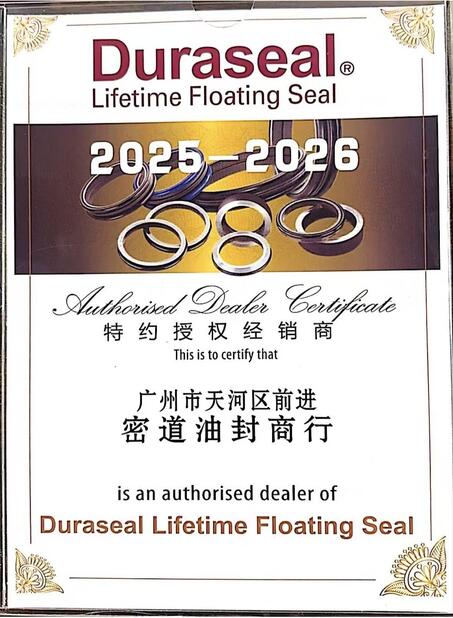

Company Profile

Mido Oil Seal was founded in 2007, which is a company specializing in the sale of construction machinery oil seals. Gathering oil seals from world's famous factories, with currently over 1,000 varieties in stock. The main service is construction machinery and engineering machinery.

The company has a total of three store and a warehouse now, one of which serves as the Foreign Trade Department to customer reception and product display. The most important thing is that we have a professional team for purchasing, selling, packing, shipping and after-sale service.

Our CEO Mr. Hu has been engaged in the oil seal industry since 1995. As one of the founders, he founded the Guangzhou Construction Machinery Industry Association and served as its president.

According to the actual situation of the Chinese excavator maintenance market, he has continuously studied, researched, innovated, introduced and developed high-quality oil seal repair kits that meet the real needs of the market. Ensure that customers can buy High-performance anti-leakage effect and long-term oil sealing effect. Based on technology leadership, the company has established a market research, quality assurance and after-sales service system to fully meet customers exact needs and has won excellent results in the industry. The reputation and word of mouth have won the continuous support of domestic and international counterparts and customers. Through long-term first-line services, we know that the promotion and use of high-quality oil seals are inseparable from your support and encouragement. We always adhere to the principle of quality first and benefit sharing to provide high-quality oil seals for the customers.

In addition to online sales, we also participate in exhibitions to have better face-to-face contact with customers.

The history of exhibition

2001 Beijing BICIS

2004 Shanghai Bauma

2005 Beijing BICIS

2006 Shanghai Bauma

2007 Beijing BICIS

2009 Beijing BICIS

2011 Beijing BICIS

2013 Beijing BICIS

2024 Moscow CTT

2024 Shanghai Bauma

FAQ

Q1. Why should I choose your products?

While operating our own manufacturing facility, we also distribute oil seals from renowned international brands. We are committed to providing one-stop solutions to meet all our customers' diverse needs. Excavator/ Loader/ Motor Grader Seal kits and Spare Parts.

Q2. What series of products does your company have?

Excavator/ Loader/ Motor Grader Seal kits and Spare Parts.

Q3. Any other good service your company can provide?

Yes. Conduct regular follow-up visits, and there are dedicated staff available online 24 hours a day

In the era of digital office, our company is committed to providing customers with comprehensive and efficient service experiences. The "Online Specialist Response" is a key component of this commitment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!