2390 Carbon Floating Ring Seals , 268*239*2 NBR Rubber Engine Oil Seal

1. Product Details

| Name |

2390 Carbon Floating Ring Seals , 268*239*2 NBR Rubber Engine Oil Seal |

| Model Number |

Mechanical Floating Seal Group |

| Quality |

Top Quality |

| Material |

NBR, FKM, Silicone, HNBR, Rubber, Metal |

| Color |

Black |

| MCQ |

10 sets |

| Hardness |

70~~90 Shores |

The 2390 Carbon Floating Ring Seal is a high-performance mechanical sealing solution designed for heavy-duty applications requiring exceptional resistance to engine oils, abrasion, and extreme operating conditions. Combining a robust metal casing with a precision-engineered NBR rubber sealing element, this floating ring seal ensures reliable performance in demanding environments such as construction machinery, automotive engines, and industrial equipment.

Key Features

· Superior Material Composition:

Crafted from Nitrile Rubber (NBR) and optional advanced materials like FKM (Fluoroelastomer), Silicone, and HNBR for enhanced chemical, temperature, and abrasion resistance. The metal component provides structural integrity and durability.

· Excellent Oil Resistance:

Ideal for engine oil sealing applications, preventing leaks and maintaining lubrication system integrity.

· High Hardness & Durability:

With a hardness of 70–90 Shore A, this seal offers outstanding resistance to deformation, wear, and extrusion under high-pressure conditions.

· Precision Dimensions:

Designed to exact specifications (2682392 mm) for a perfect fit and optimal sealing performance.

· Wide Applicability:

Suitable for use in automotive engines, hydraulic systems, industrial machinery, and construction equipment.

· Top Quality Assurance:

Manufactured to international standards, ensuring reliability, longevity, and consistent performance.

Technical Specifications

· Product Name: 2390 Carbon Floating Ring Seals

· Model Number: Mechanical Floating Seal Group

· Material: NBR (Standard), with options for FKM, Silicone, HNBR, Rubber, and Metal components

· Color: Black

· Hardness: 70–90 Shore A

· Minimum Order Quantity (MOQ): 10 sets (custom orders negotiable for larger quantities)

· Key Applications:

· Engine oil seals

· Hydraulic systems

· Rotary shaft seals

· Construction and agricultural machinery

· Industrial pumps and compressors

Applications

· Automotive: Engine crankshafts, transmission systems, and differentials.

· Heavy Machinery: Excavators, bulldozers, and loaders.

· Industrial Equipment: Pumps, compressors, and gearboxes.

· Agriculture: Tractors and harvesting machinery.

Benefits

· Leak Prevention: Ensures a tight seal against engine oils and lubricants.

· Long Service Life: Resists wear, heat, and chemical degradation.

· Easy Installation: Precision-engineered for seamless integration into existing systems.

· Cost-Effective: Reduces downtime and maintenance costs by providing a reliable sealing solution.

Packaging & Delivery

· Packaging: Secured in individual PP bags or custom packaging to prevent damage during transit.

· Lead Time: 3–7 days after order confirmation (subject to quantity and customization).

Why Choose This Seal?

This Mechanical Floating Seal Group is engineered for applications where reliability and durability are critical. Its advanced material options (NBR, FKM, Silicone, HNBR) make it adaptable to various operational environments, while its precise design ensures compatibility and performance.

Ordering Information

· MOQ: 10 sets (negotiable for larger projects).

· Customization: Available upon request (material, size, hardness).

· Contact: Reach out for pricing, bulk discounts, and technical support.

Material

Other material of oil seal Silicone,Metal&stainless steel, PTFE, etc

| Compound |

Hardness,Shore A |

Tensile strength,Mpa |

Elongation at break,% |

Temperature range |

| NBR |

60±5 |

≥12 |

≥300 |

-35℃~100℃ |

| HNBR |

60±5 |

≥13 |

≥350 |

-30℃~150℃ |

VMQ

(Silicone rubber) |

60±5 |

≥6 |

≥300 |

-50℃~200℃ |

FPM/FKM

(Fluorine rubber ) |

60±5 |

≥7 |

≥200 |

-10℃~180 |

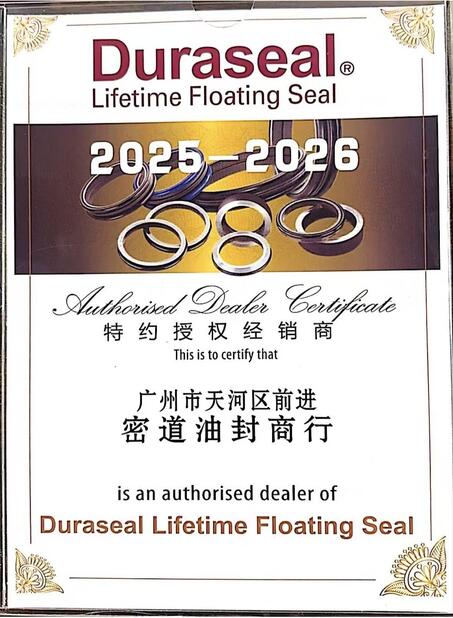

2. Company Profile

Guangzhou Midao Oil Seal is a recognized supplier specializing in high-quality, durable oil seals and sealing solutions for the machinery industry, including construction equipment like excavators. They serve both the Chinese and international markets.

The history of exhibition

2001 Beijing BICIS

2004 Shanghai Bauma

2005 Beijing BICIS

2006 Shanghai Bauma

2007 Beijing BICIS

2009 Beijing BICIS

2011 Beijing BICIS

2013 Beijing BICIS

2024 Moscow CTT

2024 Shanghai Bauma

FAQ

Q1. Why should I choose your products?

While operating our own manufacturing facility, we also distribute oil seals from renowned international brands. We are committed to providing one-stop solutions to meet all our customers' diverse needs. Excavator/ Loader/ Motor Grader Seal kits and Spare Parts.

Q2. What series of products does your company have?

Excavator/ Loader/ Motor Grader Seal kits and Spare Parts.

Q3. Any other good service your company can provide?

Yes. Conduct regular follow-up visits, and there are dedicated staff available online 24 hours a day

In the era of digital office, our company is committed to providing customers with comprehensive and efficient service experiences. The "Online Specialist Response" is a key component of this commitment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!